Unlock Efficiency With Our Electric Pilot Valve: Your Ultimate Click To Action Solution

Electric Pilot Valve: Enhancing Efficiency and Control in Industrial Applications

Introduction

Dear Smart Readers,

3 Picture Gallery: Unlock Efficiency With Our Electric Pilot Valve: Your Ultimate Click To Action Solution

Welcome to another informative article where we delve into the world of industrial valves. Today, we’ll be exploring the fascinating realm of electric pilot valves. These innovative devices play a crucial role in enhancing efficiency and control in various industrial applications. In this article, we will provide you with a comprehensive understanding of electric pilot valves, their advantages and disadvantages, and answer some frequently asked questions. So, let’s dive in!

Overview

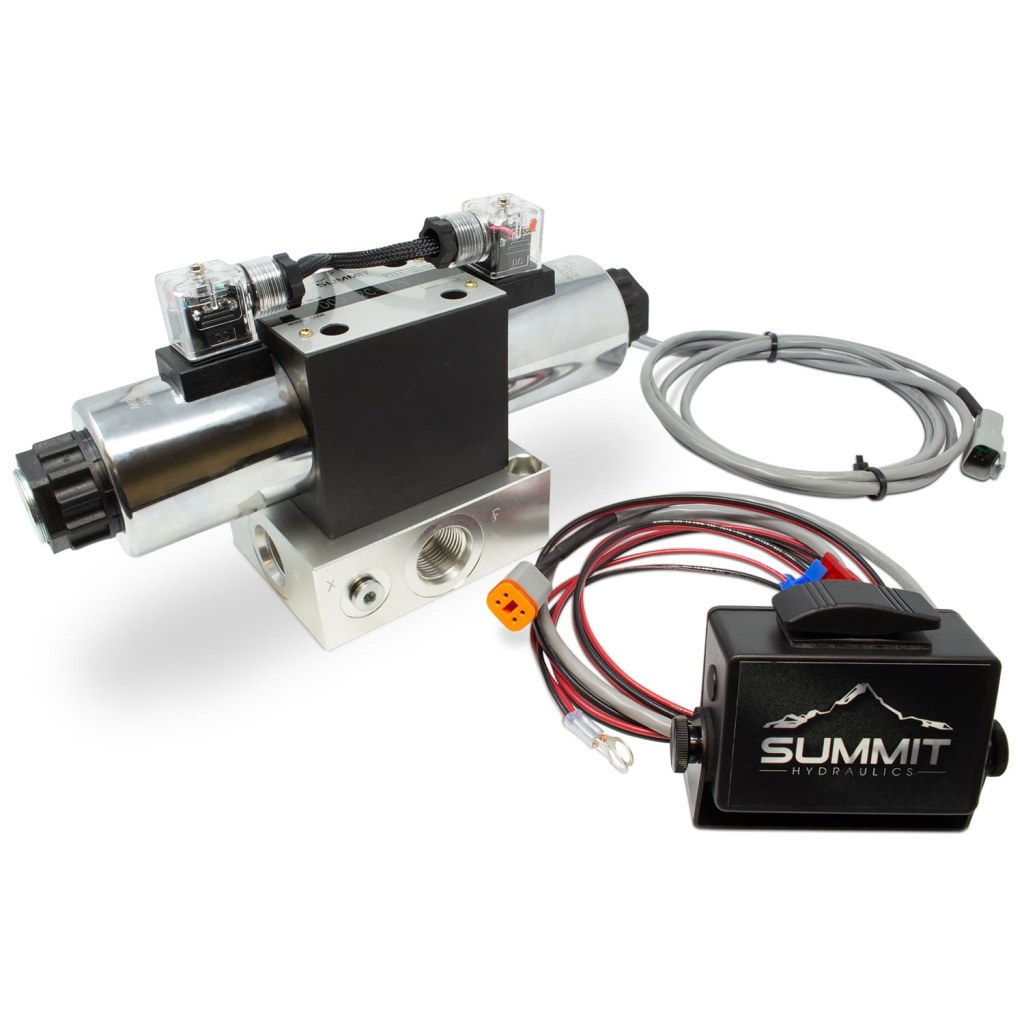

Image Source: summit-hydraulics.com

Electric pilot valves are essential components in industrial systems, controlling the flow of fluids and gases with precision. These valves act as a pilot or control mechanism for larger valves, helping to regulate pressure, temperature, and flow rates in diverse industrial processes. With their advanced technology and reliable performance, electric pilot valves have become indispensable in sectors such as manufacturing, oil and gas, chemical processing, and more.

In this table, we have summarized all the important information about electric pilot valves:

Image Source: summit-hydraulics.com

Feature

Description

Type

Various types available, including solenoid-operated, motorized, and proportional valves.

Function

Regulate fluid or gas flow, pressure, temperature, and provide precise control.

Working Principle

Utilize electrical signals to actuate the valve, allowing or blocking the flow.

Image Source: summit-hydraulics.com

Applications

Used in industries such as manufacturing, oil and gas, chemical processing, and more.

Advantages

Enhanced control, improved efficiency, reduced maintenance, and increased productivity.

Disadvantages

Potential electrical failures, higher initial cost compared to traditional valves.

FAQs

Answers to frequently asked questions about electric pilot valves.

What is an Electric Pilot Valve?

🔍 An electric pilot valve is a specialized valve that assists in controlling the flow, pressure, and temperature of fluids and gases in industrial processes. It works in conjunction with larger valves, acting as a pilot or control mechanism to regulate the overall system. The electric pilot valve operates through electrical signals, allowing precise control and automation.

Who Uses Electric Pilot Valves?

👥 Electric pilot valves are extensively used in industries that require precise control over fluid and gas flow. Manufacturers, oil and gas companies, chemical processors, and other sectors heavily rely on electric pilot valves to optimize their processes and reduce manual intervention. These valves are a vital component for engineers, technicians, and operators involved in industrial automation.

When to Use Electric Pilot Valves?

⏰ Electric pilot valves are typically employed in applications where precise control and automation are paramount. They are especially useful when there is a need to regulate the flow, pressure, and temperature of fluids or gases in real-time. Whether it’s adjusting the flow rate in a manufacturing assembly line or controlling the temperature in a chemical reactor, electric pilot valves offer the accuracy and responsiveness required for such tasks.

Where are Electric Pilot Valves Used?

🌍 Electric pilot valves find their application in various industries and sectors worldwide. Manufacturing plants utilize these valves to control the flow of liquids or gases in production lines. In the oil and gas sector, electric pilot valves are employed to regulate the pressure and flow rates of hydrocarbons during drilling and refining processes. Additionally, they play a crucial role in controlling chemical reactions and maintaining specific conditions in chemical processing plants.

Why Choose Electric Pilot Valves?

🔍 Electric pilot valves offer several advantages over traditional valves, making them a preferred choice for many industries. Firstly, these valves provide enhanced control and precision, ensuring optimal performance and efficiency in industrial systems. Secondly, electric pilot valves offer improved reliability and durability, reducing maintenance and downtime. Moreover, these valves enable automation and integration with control systems, streamlining processes and increasing productivity.

How Do Electric Pilot Valves Work?

🔧 Electric pilot valves operate on the principle of utilizing electrical signals to actuate the valve mechanism. When an electrical signal is received, the valve opens or closes, allowing or blocking the flow of fluid or gas. This electrical actuation ensures quick response times and precise control. The valves can be programmed and controlled remotely through a control system, offering flexibility and adaptability to changing process requirements.

Advantages and Disadvantages of Electric Pilot Valves

Advantages:

👍 Enhanced control and precision in regulating flow, temperature, and pressure.

👍 Improved reliability and durability, reducing maintenance and downtime.

👍 Increased productivity and efficiency in industrial processes.

👍 Automation and integration capabilities for seamless control.

👍 Remote programming and monitoring, allowing flexibility and adaptability.

Disadvantages:

👎 Potential electrical failures leading to operational disruptions.

👎 Higher initial cost compared to traditional valves.

👎 Requires skilled technicians for installation and maintenance.

👎 Limited compatibility with certain fluids and gases.

👎 Reliance on power supply for operation.

Frequently Asked Questions (FAQs) about Electric Pilot Valves

1. What are the different types of electric pilot valves?

🔍 Electric pilot valves come in various types, including solenoid-operated, motorized, and proportional valves. These types offer different levels of control and adaptability depending on the specific application requirements.

2. Are electric pilot valves suitable for high-pressure applications?

🔍 Yes, electric pilot valves can be designed and built to handle high-pressure applications. It is crucial to select valves that are rated for the desired pressure range to ensure optimal performance and safety.

3. Can electric pilot valves be used with corrosive fluids?

🔍 Electric pilot valves can be constructed from materials that are resistant to corrosion, making them suitable for use with corrosive fluids. However, it is essential to verify the valve’s compatibility with specific fluids and consult with manufacturers for the appropriate materials.

4. How often do electric pilot valves require maintenance?

🔍 The maintenance frequency of electric pilot valves depends on various factors such as the environment, the type of fluid or gas being controlled, and the valve manufacturer’s recommendations. Regular inspection and servicing are necessary to ensure the valves’ continued performance and extend their lifespan.

5. Can electric pilot valves be retrofitted into existing systems?

🔍 Yes, electric pilot valves can often be retrofitted into existing systems, provided there is compatibility in terms of size, fitting, and control interfaces. It is advisable to consult with experts or manufacturers to ensure proper integration and avoid any potential issues.

Conclusion

In conclusion, electric pilot valves are invaluable components that play a vital role in enhancing efficiency and control in industrial applications. With their precise control, automation capabilities, and reliability, these valves offer numerous advantages over traditional valves. However, it is crucial to consider the specific requirements and potential limitations when choosing electric pilot valves for a particular application. By understanding the functionality and benefits of electric pilot valves, industries can optimize their processes, improve productivity, and stay at the forefront of innovation.

Final Remarks

Dear Smart Readers,

We hope this article has provided you with valuable insights into electric pilot valves and their role in industrial applications. As with any technical component, it is essential to consult with experts and manufacturers when implementing electric pilot valves in your systems. Stay informed, embrace innovation, and continue optimizing your processes for a more efficient future.

This post topic: Electric